Fuel / Injectors

Originally Posted by Merlin

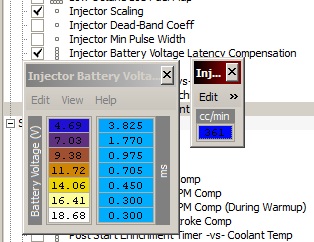

Fuel injectors have to physically move the pintall from the seat before fuel can flow. This take a finite period of time and which changes as the battery voltage varies. As the voltage is lowered, the time required to lift-off or open is increased. There is also a corresponding time delay when the injector is de-energised to the actual fuel shut off. This closing period is much shorter than the opening time and the closing period gets shorter as the battery voltage is raised. The combination of these parameters is called INJECTOR LATENCY. Different make and model injectors will have different latency specifications.

The only two values you need to modify are the Injector Scaling and Battery Latency Comp tables when installing larger injectors. The other tables are just there for learning purposes and can be ignored.Setting the scaling is simple. Just enter the rated size of the injectors you are running for pump gas. If you’re running E85, take the rated size and multiply it by .7 and use that number. This will add 30% enrichment needed for burning alcohol.The latency requires a little bit of research. This table is a great reference!

Note: You can rescale the voltage side of the table to match the chart if you please.

Injector Latency scaling equation is a function of the Injector Dead-Band Coefficient. There’s no need to modify this value. It’s needed for figuring out which Latency Scaling the table lookup value is used.

Discussion Here: Disassembly: Fuel Tables

This page was posted on Tuesday, April 16th, 2013 at 11:04 pm by bfarnam and last modified on Friday, April 19th, 2013 at 11:32 pm by bfarnam