About

Everything you wanted to know about the Official Clone and Clone² ECUs, and then some!

This was started way back in early 2008 and late 2009 when Jeff (aka Gatechrasher) first discovered that there are flashable ECUs out there. Jeff started the original decompile, but could not find any other “compatible” hardware. That’s when I got involved. Through extensive research (and countless ECUs), Jeff and I were able to determine which ECUs were flash “compatible” and which were not. This information was shared among the 3S Tech Community Forum for help with vetting and testing.

In 2010 I started picking up the coding reigns and published the first list of “compatible” hardware. I then created the first “Big Maps” ROM, which stayed in Beta due to the lack of testers. Soon after other people started jumping on the bandwagon and running willy nilly. Hype was building and Jeff’s and my time was severely limited.

In 2011 Greg (aka Monochrome) came along and picked up the coding and started developing Chrome leaving me to develop the hardware.

After a long time in testing to ensure that this is a 100% COMPLETE VR4 ECU, I am proud to offer the Clone ECU and now the Clone² ECU!

What makes these different?

These are professionally remanufactured ECUs that have gone through an extensive process including a one hour final drive test in a TRUE 1999 3000GT VR4! I have the schooling, the professional training in this type of re-work and production assembly, as well as 30+ years experience with electronics!

No one else can offer this level of testing and quality control!

The Process:

- First every incoming ECU is tested to ensure that it is working.

- Then the ECU has the conformal coating completely stripped with an approved conformal coating stripper, not brake cleaner, acetone, or alcohol like others. The proper selection of a conformal coating stripper is CRITICAL to prevent damage to the printed wiring board substrates or other components.

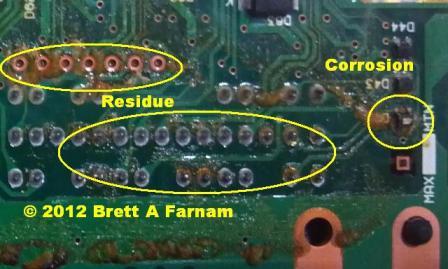

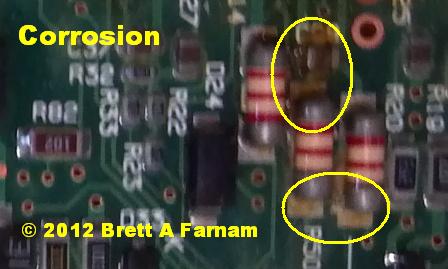

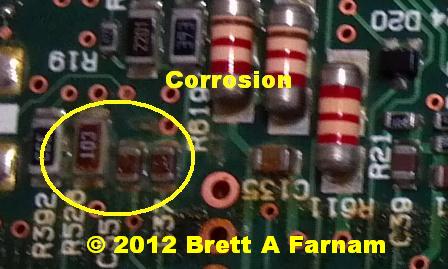

- Then the ECU is examined under 10x power for surface contamination, corrosion, and dendrites! Far too often on Mitsubishi ECUs, I have encountered extensive corrosion, dendrite growth & flux residues from flux that is not fully activated. Additionally, extensive flux residue can be found on almost ALL Mitsubishi ECUs. This can and will cause problems over time if not properly removed and reworked.

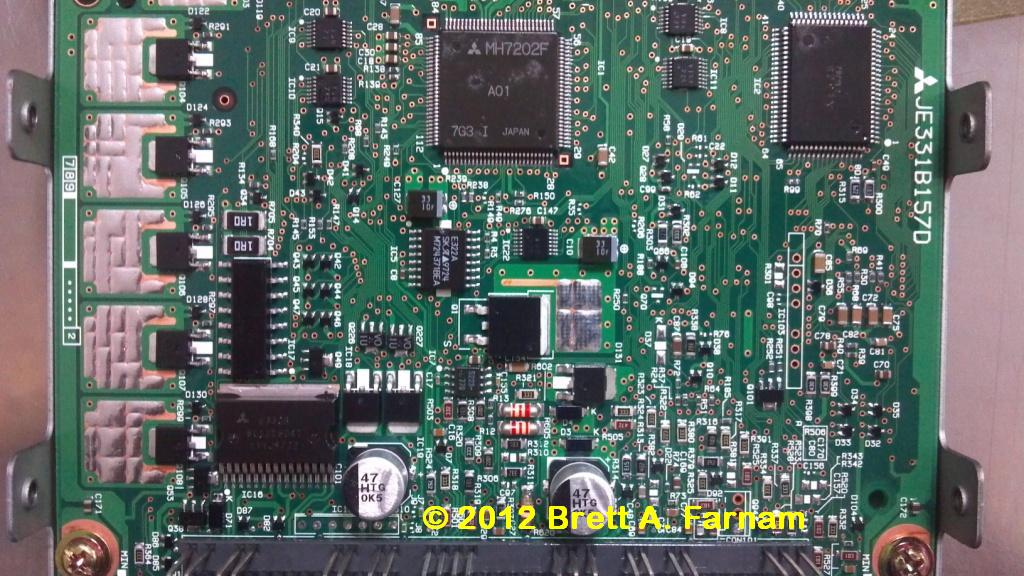

- After the ECU is examined and any rework that is required is performed, the ECU is converted to the VR4 Specification. During this process, parts are removed and parts are inserted depending on the circuit.

- The one and only capacitor, which is WAY beyond its design life of 2000 hours, is replaced BEFORE it can leak and damage the ECU. If you drove your car 1 hour a day, five days a week, 50 weeks a year (assuming you park it for vacation two weeks a year) your engine is running 250 hours a year. Considering that the 1999 is now 13 years old, that’s 3250 hours! For most daily drivers, this is very under-estimated!

- Mitsubishi used a Nichicon General Purpose 47 µF 50 V (180mA Ripple) Surface Mount Aluminum Electrolytic Capacitor. This part has a design life of 2000 hours continuous use at 105°C. This temperature can easily be obtained internally to the capacitor by a continuous ripple current greater than 180mA. This results in “soft doming” or “bulging” of the top of the capacitor which is an indicator of a pending failure.

- Almost ALL ECUs upon examination will show the “soft doming” or “bulging” which indicates a pending failure!

- This ECU which was from a 1998 had a capacitor that would have failed if it was not replaced!

- Additionally, an additional capacitor is added to help protect against voltage and current ripple. This additional capacitor normally exists only on the DOHC SL ECU to help combat the extra current draw of the variable intake plenum actuators.

- The finished product goes through even more electrical testing and is certified to be a 100%VR4 ECU!

- Once final testing is done, the ECU is cleaned of all flux residues and re-conformal coated. The ECU is the re-packaged in an appropriate case and labeled with a part number and a warranty seal.

- A slightly modified stock ROM is flashed to the ECU for a 1 hour drive test in a TRUE 1999 3000GT VR4.

- The stock ROM is set for advanced boost control, larger injectors, and an EVO MAF.

- Then the ECU is tested in my very own 1999 3000GT VR4 with ALL stock EMISSION controls (Stock Boost Gauge, Stock two stage fuel pump system setup, EVAP vent and purge, 4 O2 sensors with ECU controlled heaters, EGR, etc).

- The other people who modify these ECU’s don’t have access to a STOCK 1999 VR4 for QA/QC testing!!

- Lastly the stock Mitsubishi ROM or appropriate ROM is flashed to the ECU before delivery.